Nano Origins

Magnesium alloys and nanocomposite material - INCLUDING INTERNATIONALLY PUBLISHED WORLD'S FIRSTS

These URLs used to provide a good OVERVIEW on magnesium alloys developed as well as their tried/tested applications all over the world: (1) http://www.magnesium-elektron.com/

(2) http://magnesium.pnl.gov/ . These URLs are currently inactive but remain listed here for legacy purposes.

Please refer to this informative active URL: https://en.wikipedia.org/wiki/Magnesium_alloy .

Here's some of my contribution on magnesium alloys. Invention disclosures have been previously filed. Carbon as well as oxide, nitride, carbide and boride nanoparticles have been successfully added to AZ and ZK series magnesium alloys, as well as to selected Mg-RE (Rare Earth) magnesium alloys ...

(42) Mg-RE alloy boride in-situ nanocomposite that is stronger than selected steels in both tension and compression: Nanoscale phenomena to macroscale effects.

(41) Ultra-high strength Mg-RE/ZrB2 alloy nanocomposite (tensile yield strength exceeding 400 MPa): Strengthening by nano-LPSO-grains and nano-LPSO-layers.

(40) Biodegradable materials in clinical applications: A review

(39) Critically designing high strength or high ductility AZ / ZK / RE magnesium alloys using boron rich nanoparticles.

(38) High strength and high ductility Mg-Zn in-situ alloy nanocomposite: Formation and significant role of in-situ nanorods.

(37) Increasing strength (and ductility) of Mg-Zn alloy using dissolved Zn, Al2O3, and Cu nanoparticles.

(36) Strengthening AZ91/ZK60A hybrid alloy using Al2O3 and Cu nanoparticles.

(35) The opposing nanoscale and macroscale effects of individual B4C and AlN addition to AZ91/ZK60A hybrid alloy.

(34) Significantly addressing the overall increased presence of fine Mg-Zn phase in ZK60A/Al2O3 compared to the presence of normally less fine Mg-Al phase in AZ31/AZ91/Al2O3 magnesium alloy nanocomposites as well as formation of high strain zones (HSZs) (from particle surfaces inclusive) during tensile deformation as a significant mechanism supporting ductility enhancement in ZK60A/Al2O3 and AZ31/AZ91/Al2O3 magnesium alloy nanocomposites.

(33) Occasional drastic increase in tensile strength along with increased ductility of AZ81 using carbon nanotubes (CNTs).

(32) Nanoscale regulation of intermetallic precipitation in AZ81 using CNTs.

(31) Enhancing tensile ductility (without significant compromise in strength) of AZ81 using CNTs.

(30) Nanoscale regulation of intermetallic precipitation in AZ81 using nanosized near-spherical alumina nanoparticles.

(29) Enhancing tensile / compressive ductility (without significant compromise in strength) of AZ81 using nanosized near-spherical alumina nanoparticles.

(28) Significantly addressing the formation of high strain zones (HSZs) (from particle surfaces inclusive) during tensile deformation as a significant mechanism supporting ductility enhancement in AZ91/ZK60A/AlN and AZ31/AZ91/Si3N4 hybrid magnesium alloy nanocomposites.

(27) Significantly addressing the lower compressive strength and higher compressive ductility (or compressive toughening) of AZ91/ZK60A/AlN compared to AZ91/ZK60A based on: (a) possible shear buckling of Mg-Zn based nanoscale rod / disc intermetallic precipitated in a regulated manner in the presence of AlN nanoparticles, (b) nanoparticle stimulated nucleation(NSN) of nanograins at room temperature in the presence of AlN nanoparticles [compared to microparticle stimulated nucleation (MSN) mechanism] and (c) stacking fault formation throughout the entire nanograin (on a selective basis). Similar address made regarding comparing ZK60A/Al2O3 to ZK60A for compressive properties.

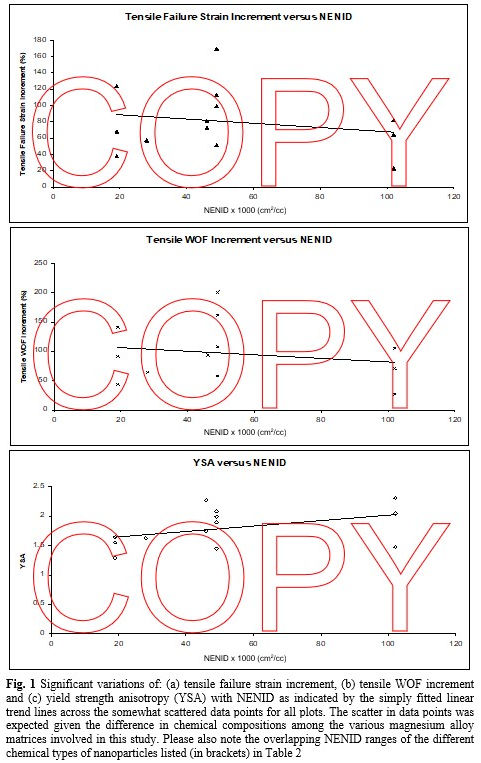

(26) Nanoscale Electro Negative Interface Densityor NENID (new theory): Quantification of the nanoparticle-alloy matrix interfacial area per unit volume in the magnesium alloy nanocomposite while taking into consideration the electronegativity of the nanoparticle reinforcement.

(25) Collectively increasing tensile ductility increment and decreasing yield strength anisotropy by decreasing NENID in magnesium alloy nanocomposites.

(24) Decreasing the possibility of nanoparticle-alloy matrix interfacial reactions by decreasing NENID, taking into account thermodynamic considerations.

(23) Elucidation of 2 joint mechanisms at nanoscale that enable tensile strength and ductility of magnesium alloy nanocomposites to be simultaneously enhanced.

(22) Nanoscale regulation of intermetallic precipitation in hybrid alloy AZ91 / ZK60A using nanosized near-spherical aluminium nitride nanoparticles.

(21) Enhancing tensile strength and compressive ductility of hybrid alloy AZ91 / ZK60A using nanosized near-spherical aluminium nitride nanoparticles.

(20) Nanoscale regulation of intermetallic precipitation in hybrid alloy AZ31 / AZ91 (despite the catalyzing nature of Mg in the intermetallic precipitation) using nanosized near-spherical titanium carbide nanoparticles.

(19) Simultaneously enhancing tensile strength / ductility of hybrid alloy AZ31 / AZ91 using nanosized near-spherical titanium carbide nanoparticles.

(18) Nanoscale regulation of intermetallic precipitation in ZK60A using silicon nitride nanoparticles.

(17) Simultaneously enhancing tensile strength / ductility and compressive ductility of ZK60A using nanosized near-spherical silicon nitride nanoparticles.

(16) Nanoscale regulation of intermetallic precipitation in ZK60A using titanium carbide nanoparticles.

(15) Simultaneously enhancing tensile strength / ductility and compressive ductility of ZK60A using nanosized near-spherical titanium carbide nanoparticles.

(14) Simultaneously enhancing tensile strength / ductility and compressive strength or ductility of ZK60A using nanosized near-spherical alumina nanoparticles.

(13) Simultaneously enhancing tensile strength / ductility and compressive strength of hybrid alloy AZ31 / AZ91 using nanosized near-spherical silicon nitride nanoparticles.

(12) Simultaneously enhancing tensile strength / ductility and compressive strength of hybrid alloy AZ31 / AZ91 using nanosized near-spherical alumina nanoparticles.

(11) Simultaneously enhancing tensile and compressive strength and ductility of hybrid alloy AZ31 / AA5083 using CNTs.

(10) Nanoscale regulation of intermetallic precipitation in ZK60A using CNTs (compared to non-regulation of intermetallic precipitation in AZ31).

(9) Simultaneously enhancing tensile strength / ductility and compressive ductility of ZK60A using CNTs.

(8) Tailoring the tensile and compressive response of ZK60A using nanosized near-spherical alumina nanoparticles.

(7) Simultaneously enhancing strength, ductility and stiffness of AZ31 using nanosized near-spherical alumina nanoparticles and carbon nanotubes (CNTs), together with mm-scale Al alloy core reinforcement.

(6) Simultaneously enhancing tensile and compressive strength and ductility of AZ31 using nanosized near-spherical alumina nanoparticles and CNTs, with comparison of reinforcement integration methods.

(5) Micro-engineering the stressed macrointerface in Mg based / Al based macrocomposites and consequently simultaneously enhancing tensile strength, stiffness and work of fracture (WOF) of AZ31.

(4) Enhancing tensile strength and ductility of Mg by resembling natural tree trunk growth ring structure.

(3) Enhancing tensile and compressive ductility and WOF of Mg by integrating it with mm-scale Al reinforcement and heat treating.

(2) Improving thermal stability and dynamic stiffness of Mg by integrating it with mm-scale Al reinforcement.

(1) Integrating Mg and Al using solidification processing coupled with hot coextrusion to form bimetal Mg / Al macrocomposite, without significant and detrimental formation of intermetallics.